– LAB Anlagenbau – Schüttgut Entnahme Förderung Dosierung und Bevorratung aus einer Hand

LAB Extraction equipment

Problem

Slow-flowing, powdery bulk materials often tend to form bridges or chimneys in the container, and thus become difficult to empty. Even slight moisture or generation of heat makes the bulk materials form into lumps.

Solution

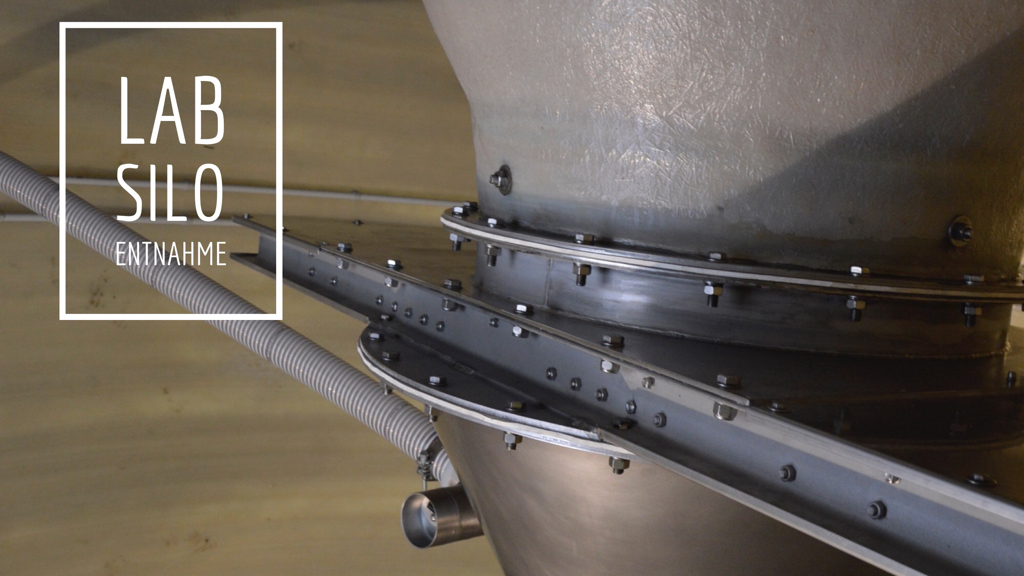

By using LAB extraction & metering technology, there are no outflow problems that occur; it works without any expensive jolting or fluidising technology and breaks up lumps during the extraction process. (EUR patent)

Rough and fine metering takes place. The rough metering operation allows an accuracy down to +/- 100g per released quantity. With the smaller LABOMATS VD100 or VD200, even +/-10g/released quantity.

Depending on the company size or the existing system, the bulk material can be extracted from sacks, Big Bags, LAB interchangeable containers or silos. The extraction technology is identical in all cases and can even be combined with an existing plant.

Larger quantities can be extracted, for example, from the Big Bag and small quantities which are also only required for certain recipes, are extracted with the manual suction lance.