– LAB Anlagenbau – Schüttgut Entnahme Förderung Dosierung und Bevorratung aus einer Hand

Silo

Problemstellung

Besonders schwerfließende, staubige Schüttgüter werden ungern in großen Gebinden gelagert da sie bei längeren Standzeiten zur Klumpen Bildung neigen oder stark verdichten. Während der Entnahme erschwert oft Brücken- oder Kaminbildung eine kontinuierliche problemlose Entnahme.

Bei besonders hohem Schüttgut Bedarf ist die Einlagerung im Silo jedoch die wirtschaftlichste.

Lösung

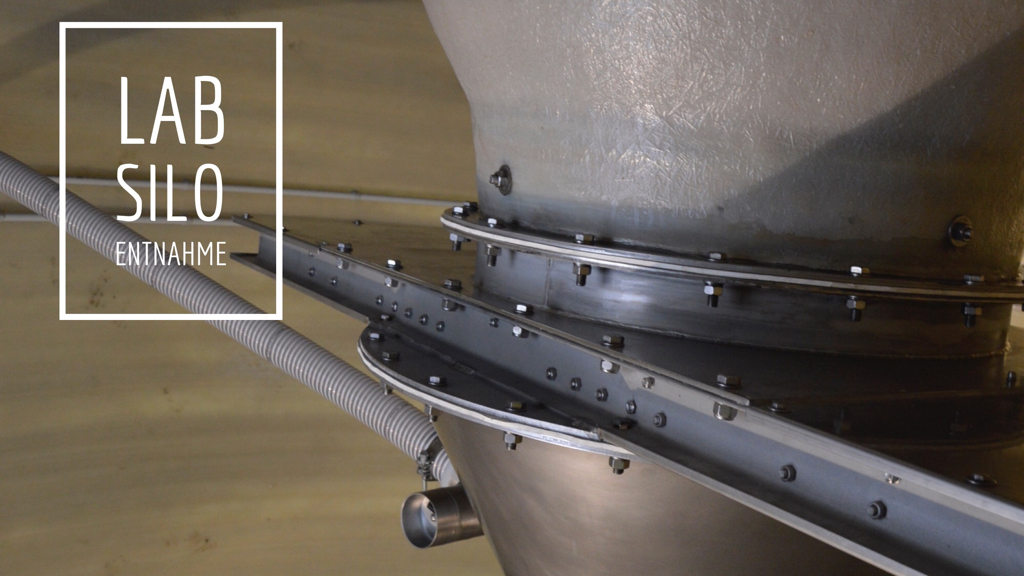

Die LAB-Silo-Entnahme erfolgt absolut staubfrei und ermöglicht eine Entnahme aus dem Silo ohne Brücken- oder Kaminbildung. Die Entnahmetechnik wird an den Silokonus angeflanscht und kann somit auch an vorhandenen Silos nachgerüstet werden.

Der Lieferumfang bei der Silo Entnahmetechnik beinhaltet je nach Anforderung folgende Positionen:

Silo Variante

Die LAB Silo Entnahmetechnik kann an alle unterschiedlichen Siloversionen wie

– GFK,

– Aluminium oder

– Edelstahl-Silos angesetzt werden.

Je nach Anforderungen und Kundenwunsch bieten wir die unterschiedlichen Silo-Versionen an und organisieren auch gerne den Aufbau inkl. der LAB Entnahmetechnik, schlüsselfertig.

Ist bereits ein Silo vorhanden, passen wir die Entnahmetechnik an das vorhandene Silo gerne an.

Silo Entnahmetechnik

Die Silo Entnahmetechnik beinhaltet das LAB EU-Patent welches eine staubfreie Entnahme und Dosierung von schwerfließenden Schüttgütern ermöglicht.

Keine Dosierbehinderung durch Klumpen- oder Brückenbildung im Silo.

Silo- Absperrschieber

Der Silo Absperrschieber ermöglicht eine problemlose Wartung / Instandhaltung der Entnahmetechnik bei gefülltem Silo.

Sperrvorrichtung wird vorab geschlossen und der Entnahmetrichter kann deinstalliert und gewartet werden.

Bunkeraufsatzfilter

Für eine besonders schnelle Befüllung des Silos empfehlen wir den LAB Bunkeraufsatzfilter inkl. Gehäuse.

Dieser wird auf dem Silo-Dach installiert und garantiert eine schnelle Belüftung während des Befüll Vorgang und der Entnahme.

Abreinigung erfolgt über die LAB Ansteuerungvorgaben voll automatisch.

Silo Befüll-Anschluss

Die Silo Befüllung ermöglicht einen schnellen Anschluss des Truck mit dem Silo.

Das Befüll Ventil wird über einen Rückmeldungskontakt in der Steuerung aufgenommen.

Entsprechende Signalleuchten am Silo-Anschluss geben dem LKW-Fahrer die Rückmeldungen zum Starten des Befüll Vorgangs.

Silo Füllstandmelder

Das Paket der Füllstandmelder beinhaltet drei Sensoren

– Vollmelder

– Bestellmeldung, individuell angepasst für die optimale Anforderungsmenge

– Leermeldung

Vorteile

- Keine Brücken- Kamin oder Klumpen Bildung

- Keine Auslaufprobleme

- Genaue Dosierung

- Staubfreie Entnahme

- Entnahme von Kleinstmengen

- CO2 Einsparung im Lebensmittelbereich

Mögliche Zusätze für die Silo-Entnahme sind folgende:

- Absperrschieber, zur Wartung der Entnahmetechnik bei gefülltem Silo

- Bunkeraufsatzfilter, zur optimierten Befüllung

- Silo Befüll-Anschluss für den Truck inkl. Rückmeldungen

- Silo Füllstandmelder

- Probeentnahme

- Restlosentleerung der Entnahmestation

- Des Weiteren sind alle Anlagenbauteile auch in einer ATEX Version erhältlich